Products

Overview "Dimensions of mirrorpolished stainless steel sheets"

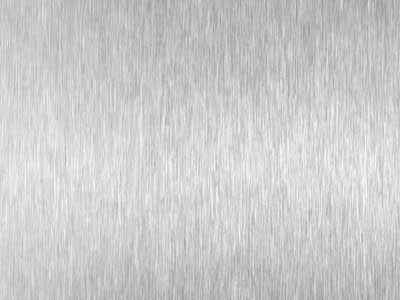

Mirrorpolished finishes for stainless steel plates

When it comes to high-gloss or mirror-polished stainless steel surfaces, mirrorINOX offers traditional and new pioneering solutions for applications in:

- Architecture

- Yacht and shipbuilding

- Automotive and electrical industries

- Medical technologies

- Container- and silo-manufacturing

- Machinery and engineering

- Aerospace and many more

mirrorINOX's polished quality is selected by artists and designers even for the most demanding art projects.

Mirrorpolished stainless steel of the highest quality

mirrorINOX is your ideal and competent partner for all polished stainless steel surfaces of the highest quality, including high-gloss polished, mirror-polished and various others.

However, since the very common terms "high-gloss polished" or "mirror-polished" often do not provide a very clear definition of the product, mirrorINOX defines its self-produced and distributed mirror-polished inox surfaces in several quality levels in order to create more transparency for the customer when inquiring and more clarity when ordering the material:

How do we mirrorpolish stainless steel plates?

During mechanical polishing, the upper layer of the inox surface is removed by our polishing lines and with the help of polishing agents, a flat, smooth and as flawless as possible finish is created. Only after that does the actual mirror polishing take place.

Different results (qualities) of stainless steel mirror finish can be achieved depending on:

- The base material,

- The base surface finish,

- Various machine parameters and processes

Measurable values such as roughness and gloss plus the visual appearance and approval serve as the basis for verification.

Mirrorpolished stainless steel: applications for yachts, architecture and more

The high-quality products manufactured by mirrorINOX are in great demand, especially with the design applications in the field of:

- Architecture: façades, indoor and outdoor walls, roofing sheets, elevators

- Yacht: boat fittings, hardware and accessories

- Shopfitting: reception desks, escalators, etc.

- Lighting and furniture construction

Whether we mirror polish inox steel for yachts or shops, you can always expect the highest quality from us. Even in the extremely quality-sensitive sector of art, our products are well known and highly recognized by the most famous artists, however they like to remain anonymous.

mirrorINOX: mirror-polished stainless steel and more

mirrorINOX not only offers you mirror-polished stainless steel (sheets and plates in various lengths, widths and thicknesses – 0.5 mm, 1 mm, 2 mm, 3 mm, or even 5 and 10mm – or custom-made), but also a vast range of products and services in the field of stainless steel surface finishing.

With many years of expertise and experience, mirrorINOX is the manufacturer of the world's largest range of different quality levels, such as our stainless steel mirror finishes Mirror No.7, Super Mirror No.8, Marine Mirror No.9 and Perfect Mirror No.10®.

For such products, mirrorINOX uses stainless steel grades:

- AISI 304/304L

- AISI 316/316L

- AISI 316Ti

- AISI 318

Due to its unique expertise, mirrorINOX is able to manufacture custom stainless steel plates in dimensions or lengths, widths or thicknesses that cannot be found anywhere else.

The following dimensions are possible:

|

Width: |

max. 4,000 mm max. 16,000 mm max. 100 mm |

A particularly outstanding example is the "Rock" art project, for which inox metal sheets in dimensions up to 14,937 x 3,347 x 16.0 mm and up to a weight of 6,415 kg per single sheet were polished to Perfect Mirror No.10® quality. Other stainless steel surface treatments of the highest qualities are also performed by mirrorINOX: grit polishing, vibration polishing, bead blasting, fluid forming, PVD/TiN and nanoINOX®-coating.

Mirror-polished stainless steel: properties and advantages

In principle, we differentiate here between technical applications, which, for instance, require the requested surfaces to have the lowest possible roughness (Ra value).

Such properties play a major role especially in applications like container- and silo-manufacturing, mechanical engineering, food and medical technology, where adhesion to the inox surfaces has to be avoided by using material that is as smooth as possible.

Other customers request a certain reflectivity from the metal finish, for example in the lighting industry.

Another increasingly popular use of mirror-polished stainless steel sheets is found in architecture, shopfitting, yacht and shipbuilding, where the focus is very strongly on an optically first-class result in terms of the visual quality of the stainless steel sheets.

In addition to a flawless appearance, more advantages of a mirror finish are the low weight ratio compared to glass mirrors, the very good workability and, immensely important when used in public buildings or other highly frequented locations such as train stations, airports and others, mirror-finish stainless steel plates are unbreakable, fireproof and vandal-proof.

Mirrorpolished Finishes

Bead-blasted finishes for stainless steel plates

In many fields of expertise, high-quality applications increasingly request a uniformly matte, very homogeneous surface, which should not only be non-directional but also offer little to no reflectivity.

Such a decorative and functional surface is created by blasting onto metallic materials such as stainless steel/inox, aluminum, and even non-ferrous metals like brass or copper at a very high speed with glass beads or with alternative blasting media of various bead sizes.

mirrorINOX: our range of bead-blasted finishes for stainless steel sheets

The mirrorINOX products in its bead blasting range are called BEADS.

The different variations of the BEADS finish are as follows:

|

BEADS 0 |

- glass beads with a very fine finish - glass beads with a fine finish - glass beads with a medium finish - glass beads with a coarse finish - glass cullets - ceramic beads - corundum beads |

Stainless steel is the most requested base material. Additionally, we also offer alternative solutions based on aluminum, brass, copper, titanium and others.

mirrorINOX produces BEADS in the following stainless steel plate dimensions:

|

Width: |

max. 2,000 mm max. 6,000 mm max. 30 mm |

Additional specifics of BEADS surfaces:

- Inox and other metal sheets can be blasted on the front and reverse sides

- Blasted finish to be produced according to customer’s specifications

- Numerous finishes and effects, i.e. gradient blasting, are possible

What is stainless steel glass bead blasting?

The terms “glass bead blasting”, “bead blasting stainless steel” or “bead-blasted stainless steel” commonly refer to the surface treatment of sheets or workpieces where blasting media such as glass beads, ceramic beads or corundum beads hit the material.

The size and roughness of the blasting media, the pressure and the speed during the blasting process can be altered in order to achieve different results in terms of visual effect, reflectivity and roughness. As such, inox steel bead blasting is a very flexible process at mirrorINOX, leading to high-quality finishes.

Glass-bead-blasted stainless steel: what are the applications?

In general, these timelessly elegant, visually attractive, metallic surfaces are used in the fields of:

- Architecture: building construction, outdoor walls, balustrades

- Elevators: lift wall panels, doors, and accessories

- Façades

- Shopfitting: indoor wall decoration, escalators, reception areas

- Yacht and shipbuilding: boat accessories and fittings

- Art: sculptures and other works of art

As such, bead-blast finish stainless steel has many applications within countless professional fields.

It can also be found in high-quality machinery and industrial engineering.

mirrorINOX offers custom-sized stainless steel sheets with maximum dimensions of 2,000 mm (width) 6,000 mm (length) and 30 mm (thickness) for its bead-blasted finishes.

Stainless steel glass beadblasting vs. sandblasting: what is the difference?

For the visually less demanding requirements of industrial and heavy industrial applications, materials like stainless steel or other metals are requested very frequently, resulting in different blasting processes such as those using sand ("sandblasting") or metal beads (“shot peening”).

In stark contrast to these processes, the Injector/Venturi blasting line operated by mirrorINOX is perfectly suited for the production of the BEADS product line with its particularly uniform, very homogeneous surfaces for the highest quality applications.

mirrorINOX: bead-blasted stainless steel of the highest grade and quality

Our highest quality is based on precise and strictly documented production including measurement of the roughness and the degree of gloss, as well as a professional assessment of the visual appearance of the blasted material by our skilled and experienced staff.

Using this thorough quality control and measuring, all values such as the gloss, color and roughness of each single inox metal sheet are precisely recorded.

Therefore, mirrorINOX is able to guarantee maximum reproducibility and the highest possible quality for the most demanding applications, whether in the engineering and machinery industry (e.g., appliances, tanks, silos, etc.) or architecture, art, etc.

In addition, our vast and efficient production capacities ensure the fastest possible delivery service.

Coming with extensive knowledge and years of experience, mirrorINOX is your ideal partner for bead-blasted finishes on stainless steel and other metals: glass bead, ceramic bead, glass cullet and corundum bead-blasted metal surfaces.

A remarkable number of major projects, numerous other applications in the fields of art, architecture, elevators, facades, shops, ships, yachts and machinery as well as plant engineering and, last but not least, the number of satisfied customers are an impressive testimony to the capabilities mirrorINOX has honed over the years, both for bead-blasted stainless steel as well as other services in terms of stainless steel surface finishing.

Beadblasted Finishes

Vibration polishing: circular-brushed finishes for stainless steel plates

Vibration finish or non-directional polishing is known in the market by various names, e.g., circular brushing, circular polishing, vibration polishing, Vortex or non-directional polish and, due to its particular visual appearance, the finish is even poetically referred to as "Angel Hair".

At mirrorINOX, this particular product range is called VIBES.

mirrorINOX: circular-brushed stainless steel sheets of the highest quality

The vibration-polishing line used by mirrorINOX is one of the most modern and efficient in today's markets.

It offers great flexibility in applying various polished-finish designs, as well as sufficient capacity for even the largest projects.

Many years of experience in the production of circular-polished inox metal sheets, meticulous recording of surface roughness and gloss plus controlled and precise production processes are the perfect basis for this high-quality finish manufactured by mirrorINOX.

Our large production capacities also guarantee the fastest possible delivery service.

At mirrorINOX, we offer various dimensions, grades and finishing options for our circular-brushed stainless steel sheets.

Dimensions

mirrorINOX produces its VIBES finish with the following stainless steel plate dimensions:

| Width: Length: Thickness: |

max. 2,000 mm max. 6,000 mm max. 30 mm |

Materials / Grades

mirrorINOX offers vibration-polished stainless steel in the following grades:

- AISI 304

- AISI 316

- AISI 316L

- AISI 318 LN

- AISI 316Ti

- Other materials such as aluminium or brass on request

Options

At mirrorINOX, circular-brushed stainless steel sheets and plates can also be produced in combination with a wide range of colors. When applying color to vibration-polished inox surfaces, we use our PVD/TiN and nanoINOX® AFP/ETC coating processes.

Any variation of vibration finish can also be coated with our CLEAR nanoINOX® AFP/ETC coating which adds a transparent, protective layer that makes the surface more pollution-repellent and much easier to clean. Such properties are not only beneficial in public, highly frequented locations and areas where direct contact with the surface is possible, but also on façades and other applications where cleaning requires effort and cost.

Vibration-polished stainless steel: the benefits of circular brushing

The process of vibration finishing creates a non-directional, homogeneous, matte surface. Aside from its visual attractiveness, an additional advantage of this circular-brushed finish is that fingerprints or small scratches are not visible on the -polished inox steel surface.

To sum up its properties, vibration-polished or circular-brushed stainless steel surfaces are characterized as follows:

- Low roughness values (Ra)

- An attractive, matte, patina-style appearance

- High resistance to minor surface damage

- Can be cut and installed non-directionally

Applications of circular-brushed stainless steel sheets

Circular-polished inox sheets and plates are often used in areas where frequent contact with the surface is present, for example in:

- Kitchens and catering (worktops, stainless steel credenzas and sinks, equipment and accessories, cladding for built-in appliances)

- Bathrooms (washbasins)

- Construction of appliances for the food industry

- Construction of devices for the pharmaceutical industry

- Container and vessel construction

- Architecture (façades, interior cladding, elevator, etc.)

mirrorINOX – Expert in stainless steel surface treatment and finishing

Please feel free to contact us and send us your enquiries about vibration-polished or circular-brushed sheets, plates or other surfaces.

mirrorINOX also offers other inox steel finishes and surface treatment services: grit, brush, HAIRLINE and mirror polishing, bead blasting, PVD/TiN and nanoINOX® AFP/ETC coating.

Visit our "products" page and discover our full range of high-quality finishes!

Vibrationpolished Finishes

Grit-polishing: grit finishes for stainless steel plates

There are different types of grit finishes for stainless steel and other metal sheets:

- Grit polishing

- Brush polishing

- Satin grit polishing

- Hairline grit polishing

- Cross grit polishing

- Etc.

When applying these mechanical surface treatment processes, various patterns and designs of polishing are achieved with the help of a variety of abrasive media, different machinery and machinery parameters.

The desired finishing results are defined by the customer's optical specifications, for example in architecture and other design applications, in which details such as the reflections but also the haptics of the surface play an extremely important role (e.g., building architecture, indoor and outdoor wall designs, escalators, balustrades, etc.).

Since inox steel sheets do not usually have a very attractive appearance and are often not sufficiently reproducible when they leave the mill or service center, mirrorINOX processes their surface with very high-quality grit-polishing standards to provide you with a satisfactory result.

Our stainless steel grit polishing offer

- Large selection of grit patterns and finishes from very fine to very coarse

- Free-issue grit polishing, grit polishing of aluminium, brass, titanium and other services on request

- Production according to customer specifications possible: Ra grinding and other special grinding types such as CROSS, perpendicular grit polishing and others

- Values of each order and every individual sheet, such as gloss and roughness are measured and recorded, thus ensuring maximum reproducibility

- Grit polishing is also possible on both sides of the stainless steel plate (Front + Reverse)

Grit finishes on stainless steel: our grades and applications

mirrorINOX always offers you the optimal grit finish solution for stainless steel sheets or plates, such as SATIN finish sheets, whether it be small quantities of material or larger projects in the fields of:

- Architecture

- Elevators

- Escalators

- Shopfitting

- Exhibitions

- Yacht and shipbuilding

- Machinery engineering

- Etc.

Our solutions are predominately based on stainless steel grades AISI 304 and AISI 316 for outdoor applications, in particular for façade construction, as well as using raw materials such as aluminium, titanium or brass and also for grit-polished surfaces.

You can find some fascinating examples of applications here on our website.

Other highly sought-after products are finishes with extremely low Ra values. These can go as far as high-gloss surfaces (Ra value <0.1), which are required for the most demanding industrial applications, for example in:

- Container and machine construction

- Pharmaceutical and food industry

- Cleanroom and medical technology

Here again, mirrorINOX meets the highest technical requirements for stainless steel surfaces and other types of metal.

How do we grit polish stainless steel?

mirrorINOX's controlled and precisely recorded production is based on many years of experience in stainless steel grit polishing, measurement of the roughness depth and the gloss of the surface, as well as the professional assessment of the visual appearance.

In addition to that, we have sufficient production capacities to guarantee the fastest delivery service possible.

Dimensions

We offer the grit polishing of custom-sized stainless steel/inox sheets in the following dimensions and grit sizes:

Grit-polishing line 1 – Wide-belt grinding machine (Dry grinding):

|

Width: |

500 – 2,000 mm 1,000 – 7,000 mm 0.5 – 12.0 mm |

|

|

Grit/grain: |

Grain 36, 60, 120, 180, 220, 240, 320, 400, 600, brushed | |

|

Direction of polish: |

Longitudinal polish |

– up to 2,000 wide x 7,000 mm long – up to 2,100 wide x 2,100 mm long |

Grit-polishing line 2 – Narrow-belt grinding machine (Wet and Dry polishing):

| Width: Length: Thickness: |

500 – 4,000 mm |

|

| Grit/grain: |

Grain 36, 60, 120, 180, 220, 240, 320, 400, 600, 1200, brushed |

|

| Direction of polish: |

Longitudinal polish |

– up to 4,000 wide x 16,000 mm long – up to 4,000 wide x 4,000 mm long – up to 1,500 wide x 4,000 mm long |

|

*Ideally suited for large inox metal sheets, such as Quarto sheets. |

||

Ra Values

Ra < 2.0 µm / Ra < 1.2 µm / Ra < 0.8 µm / Ra < 0.4 µm / Ra < 0.2 µm /

Ra < 0.1 µm / Ra – Special grit polishing according to customer's roughness (Ra) requirements

Materials / Grades

We grit polish stainless steel sheets in the following grades:

|

AISI 304 |

1.4301 1.4401 / 1.4404 1.4435 1.4462 1.4571 |

mirrorINOX offers the grit polishing of other materials:

- Aluminium grit polishing

- Brass grit polishing

- Titanium grit polishing

mirrorINOX – stainless steel surface finishing with expertise and passion

mirrorINOX not only offers you innovative surface treatment solutions of the highest quality when it comes to grit polishing stainless steel, aluminium, brass or titanium. You will find other high-quality and technically advanced surface finishes in our portfolio, such as:

- High-gloss polished finishes - large stocks of Super Mirror No.8 (also in special grades and dimensions)

- Bead-blasted products

- PVD/TiN coated metal sheets: Gold-TiN, Black-TiN, Rose Gold-TiN and Bronze-TiN coated finishes

- nanoINOX® AFP/ETC coating

- And much more

Whether for individual applications and prototypes, for large façade projects, elevators, escalators, shopfitting, exhibition stands, yacht and shipbuilding, or for machine cladding or artworks and many others, our experienced and motivated team will advise and support you fully in your task to create and find the perfect surface.

Grit Polished Finishes

Overview "Dimensions of PVD/ TiN coated stainless steel sheets"

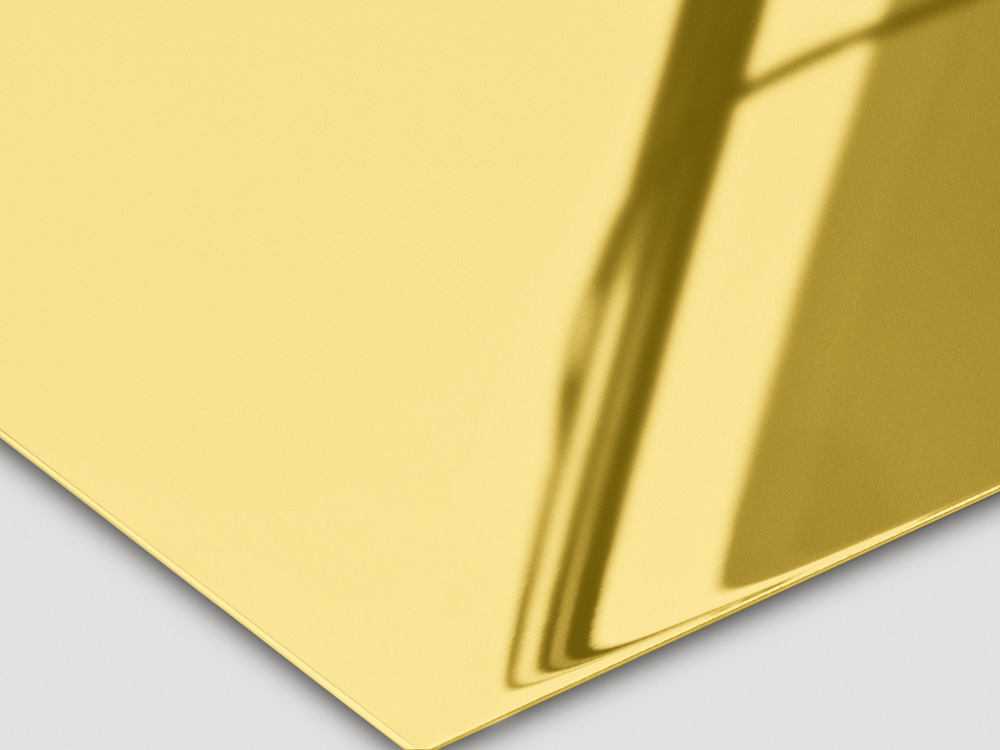

PVD-coated/TiN-coated finishes for stainless steel plates

The PVD/TiN coating process is increasingly demanded by architects, product designers and a large number of other users – in art, construction, machinery, engineering, etc.

Being an expert when it comes to stainless steel and other metal surface treatments, mirrorINOX naturally focuses heavily on using this physical vapour deposition (PVD) process to predominantly coat stainless steel sheets and other metals, having gained vast expertise with this technology.

The commonly used terms "PVD coating", "TiN coating" or "titanium nitride coating" refer, in principle, to one and the same process and are used synonymously when it comes to this particular coating of inox metal sheets.

mirrorINOX – Unmatched expertise in stainless steel PVD coating/TiN coating

Stainless steel surface treatment is our core competence. Our specialist staff have been working intensively on this unique coating technology for two decades and are constantly developing new properties and designs for potential new applications and projects.

Our two current PVD-coating lines are configured with the latest tailor-made, state-of-the-art technology. Combining both ensures outstanding results, which place mirrorINOX amongst the world's top manufacturers:

- Unmatched colour accuracy

- The largest dimensions and geometries

- High capacities and production speed when coating inox sheets and parts

An impressive array of prestigious, exclusive large-scale projects, numerous smaller objects and applications with our stainless steel finishes can be found globally and are a clear testimonial.

What is PVD-coated stainless steel?

The advantages of PVD coating / TiN coating

In contrast to alternative coatings, e.g. galvanic processes, PVD coating/TiN coating uses no toxic or environmentally harmful substances.

Additionally, the extremely thin layers of the coating are very natural in their metallic, vibrant appearance. This sets them apart from alternatives such as wet painting, powder coating or anodized finishes.

Therefore, the PVD coating process is clearly an excellent method to coat substrates. By vapour deposition, not only are physical and technical advantages created, such as an increase in hardness or improvement in corrosion resistance, but also an optically high-quality refinement of these substrates is achieved when coated with the thinner layers.

Coloured PVD-coated/TiN-coated stainless steel

In the case of stainless steel PVD, for example, the coloured surface coatings obtained with the PVD technology not only protect the substrate, but also create fascinating metallic shades which are optically extremely attractive, ranging from:

- Champagne

- Yellow-gold

- Brass

- Rose-gold

- Bronze

- Anthracite

- Black

Those fascinating colours, in combination with various basic surfaces, give the inox steel an exclusive appearance and create brilliant examples of applications in architecture and product design for both indoors and outdoors, such as:

- Building façades

- Lobby and reception areas

- Decorative walls

- Escalators

- Lifts

- Staircases

- Etc.

The process of PVD coating – how does it work?

The PVD/TiN coating of large areas (custom-sized stainless steel plates or other metal sheets) is carried out with the help of arc vapourization, in which the "target material" in the form of a solid is vapourized by means of an arc so that it can subsequently be applied to the sheet or workpiece.

By adapting suitable reactive gases, different temperatures and other machine parameters, the chemical combination of metal and non-metal achieves different colors on the surface of the sheets or workpieces.

PVD coating or TiN coating: what is the difference?

As mentioned earlier, the abbreviation PVD, which stands for "Physical Vapor Deposition" and the term "TiN", an abbreviation deriving from the chemical compound titanium nitride – a hard metallic material made of titanium and nitrogen, typically of a golden-yellow color – both define the same process of physical vapor deposition in principle and denote the same group of vacuum-based coating processes or thin-layer technologies.

We will happily advise you about these stainless steel finishes and other technical details as well as the possibilities mirrorINOX is able to offer when it comes to the PVD/TiN coating process.

PVD/TiN-coated Finishes

nanoINOX® - The nano-coating by mirrorINOX

Regardless to the specific application, the question of how to protect and ultimately nano-coat the surfaces is becoming a more and more important issue. Although there have been various so-called nano-products around for a while already, there were always too many compromises for the customer to accept.

The now available nanoINOX® AFP/ ETC coating manufactured by mirrorINOX based on the latest SolGel technology with its Anti-Finger-Print (AFP) /

Easy-To-Clean (ETC) properties gives customers a highly effective and attractive solution which, in contrast to competing products, provides simply more benefits and consequently adds more function and value to their application.

The nano-coating produced by mirrorINOX

The nanoINOX® coating produced by mirrorINOX offers unique functions and has practically limitless design options, especially on stainless steel surfaces.

Not only is it possible to choose from a myriad of color tones, surface finishes and even create one`s own exclusive customized designs.

Furthermore, properties such as color, hardness, temperature stability, corrosion and chemical resistance, transparency or workability (formability) can be controlled and enhanced by embedding various elements into the layer of the coating.

One of the most requested properties of the nanoINOX® SolGel, along with the tremendously large variety of optical and design options, are the Easy-To-Clean (ETC), AntiFingerPrint (AFP) functions (Lotus leaf effect).

It can be used both for indoors and outdoors applications, protecting the surfaces against pollution and contamination, such as fingerprints, graffiti and many others, saving massively on cleaning and maintenance costs, performing excellently under weathering, keeping project and product clean, hygienic and visually attractive.

Additional, technical functions of the coating, such as antibacterial or electrically insulating properties are also possible to be built into the layer.

The areas of application for the nanoINOX® coatings are plentiful. For example, a nanoINOX® surface can be used for catering products, in elevators, yacht interiors or as facade panels.

In stark contrast to alternative coatings, for example galvanic processes, the nanoINOX® coating does not use or leave behind any toxic or environmentally harmful substances.

The nanoINOX® new technology guarantees a very precise and strictly controlled, color-uniform reproduction when coating stainless steel sheets, regardless of raw material batch-to-batch related variables.

The industries and their applications for our nano-coating

The groups of customers and the areas of applications where nanoINOX® surfaces are used, are just as diverse as the coatings themselves:

In architecture, whether for small applications or in large projects, in the shop fitting-, sanitary- and wellness-industry, in yacht- and shipbuilding, for silos and containers, plant and mechanical engineering, in aerospace, medical or automotive technologies, for household or electrical appliances, even in art projects,

the nanoINOX® coating by mirrorINOX proves to be the ideal material.

In all these fields, the nanoINOX® coating adds value to the product or to the application by increasing the attractiveness, service life, hygiene conditions, robustness and major reduction of cleaning and maintenance costs.

What is a nano-coating?

The application of nanostructures to surfaces is generally referred to as nano-coating. It makes the surfaces superhydrophobic, so that any liquids getting in contact with the surface will form droplets and run off (lotus effect) or superhydrophilic, meaning liquids that get onto the surface form a liquid film and run off. Consequently, the nano-coating seals the surfaces and makes them water and pollution repellent. A lotus effect is achieved, facilitating the cleaning procedures, reduces the number of cleaning cycles, saving massively costs and chemicals, which is also good for the environment.

The nanoINOX® coating is based on the SolGel process, which is one to most tried and tested nano-coating.

How we apply the nano-coating

mirrorINOX applies the nanoINOX® coating, based on the latest SolGel technology, onto the surfaces with the help of a multi-head rotary atomizer. Those are predominantly prepared and cleaned stainless steel sheets finishes.

After the applying, the surfaces will be treated by running through a conveyor furnace, reaching temperatures up to 250°C.

The range of the coatings with a thickness of usually 2 and 5 microns starts off with a transparent layer and can be complemented with colour pigments of a vast variety.

Nano-coating at mirrorINOX - A brief overview of our offer

The SolGel coatings nanoINOX® produced and applied by mirrorINOX offer the customer almost limitless design options and have unique functions.

A wide variety of variants are possible as base surfaces, for example the mill finishes

- 2B

- 2R

and other surface treatments such as

- grit polished

- brushed

- mirror polished

- bead blasted

- embossed rolled

- pattern rolled

- fluid formed

- and many others

The following grades of stainless steel based substrate materials can be coated:

- AISI 430

- AISI 304

- AISI 316

- AISI 316L

- AISI 316Ti

- AISI 2205 Duplex

- Aluminum

The following dimensions can be presently coated:

| Length: Width: Thickness: |

max. 6,000 mm max. 1,500 mm max. 6.0 mm |

On request, mirrorINOX also offers nanoINOX®-coating of special dimensions and parts.

The following colors and designs are currently possible:

- CLEAR nanoINOX® (transparent)

- Champagne Classique nanoINOX®

- Gold Rosé nanoINOX®

- Abyss Black nanoINOX®

- Black Matt nanoINOX®

- Black Electrum nanoINOX®

- Blue Electrum nanoINOX®

- Green Electrum nanoINOX®

- uniqueSURPHACE®

- and other special colors and designs on request

Further special features of the nanoINOX® coatings:

- applying on face and reverse side possible

- project-related special designs + customized colours possible (based on volume of project)

- very high colour uniformity and reproducibility, regardless to variables of different raw material

- batches (Absolutely indispensable when it comes to demands of larger volume)

Nano-coating and more: mirrorINOX is your contact for stainless steel surfaces

mirrorINOXconstantly refines, develops and creates new processes and lives up to its role as a pioneer on the forefront of finding new technologies and techniques. Its most modern products such as nanoINOX® AFP / ETC coating and many others makes mirrorINOX your ideal partner for unique surface solutions, at presence and in the future to come!

mirrorINOX produces and offers a large range of fascinating products and treatment services in the field of stainless steel and other metal surfaces. Further information can be found on this website under PRODUCTS.

nanoINOX® Finishes

Eco-Etching is an eco-friendly process that applies etched designs to stainless steel without the use of acids, chemicals or hazardous without producing any toxic waste.

Available for stainless steel and other metals.

Eco-Etching Finishes

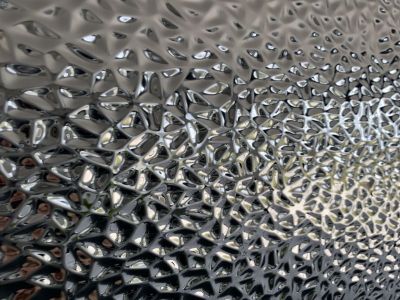

Fluid forming stainless steel by mirrorINOX

In the field of architecture, product design and other industries, new creative solutions are constantly being sought in order to create an attractive, exclusive and unique forming of different metal materials.

The fluid forming surfaces from mirrorINOX, also sometimes not quite correctly called "Hydroforming", "Hydroforming stainless steel" or "Hydroforming aluminum", are manufactured using a highly progressive, innovative and complex process of 3D fluid technology.

This forming technology sets new standards in the forming of metal and in the production of metallic structured surfaces, both in terms of aesthetics and design, as well as to the advantages relating to statics, acoustics and sun protection properties.

What is Fluid Forming?

With this technology, sheets are pressed with the help of a liquid under high pressure onto an individually manufactured tool. This processing is possible using an extremely powerful press, which was originally developed for forming processes in the automotive industry.

Where are fluid forming surfaces used?

The innovative and sustainable surfaces are used in architecture, for example as facade panels or ceiling and wall cladding in indoor and outdoor areas.

They can also be found more and more frequently in the fields of shop-fitting and exhibition-building, ship and yacht construction, but also for applications in product design and art.

In addition to their unique, visually attractive properties, the formed sheets have high strength and reduce the weight of the components through the use of thinner thicknesses.

mirrorINOX: Fluid Forming from aluminum to stainless steel

From the number of all already designed tools and the resulting structures in connection with the most diverse surface finishes based on stainless steel such as Super Mirror No. 8, BEADS, VIBES, SATIN, HAIRLINE, but also with alternative, cold-formable materials such as aluminum, copper, steel, titanium, etc., combined with colors and coatings such as PVD / TiN, nanoINOX® and others, mirrorINOX offers a unique and almost limitless number of combinations and design options.

Depending on the tool and material, a production of dimensions up to 4,000 x 2,000 mm is possible.

Of course, all this in the well-known mirrorINOX quality and delivery reliability.

As your competent partner for new solutions and designs, we support you in the realization of your drafts and ideas and together with you we want to push the limits of what was previously possible further and further.

Fluid Forming Finishes

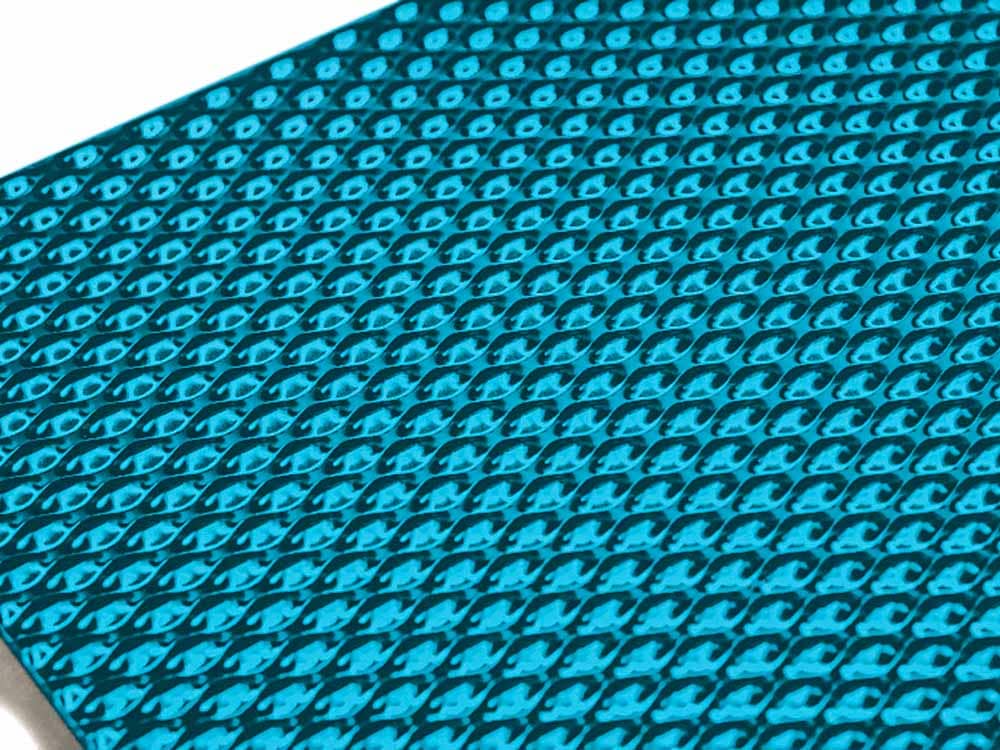

Patterned finishes for stainless steel sheets

Most of us who deal with the surface treatment and finishing of steel, stainless steel or other non-ferrous metals have an idea what the terms "rolling steel", "rolling metal sheets", "hot rolling" or "cold rolling" mean.

It becomes more specialized when it comes to terms such as "pattern rolling", "design rolling", "structure rolling", "emboss rolling" or just "designing". With this special rolling manufacturing process, various metal surfaces can be refined and their properties can be changed and improved both technically and visually.

These types of patterned stainless steel sheets are of great interest to a large number of customers from many different fields:

- Architecture: construction, outdoor and indoor areas, lifts

- Design: artwork, sculptures

- Industry: mechanical engineering, machinery, automotive

- Shopfitting: mall and shop decorations, escalators, reception desks

Pattern rolling expertise: stainless steel and other metals

The numerous advantages which are achieved by rolling metal sheets, clearly speak in favour of the patterned or pattern-rolled, and embossed surfaces from mirrorINOX:

- Improved surface quality

- Resistance to scratches and dirt

- Optical flatness

- High toughness

- Advanced technical and mechanical properties

- Visual appearance

mirrorINOX also offers various rolled structures that are exclusively manufactured and distributed.

Pattern rolling as a manufacturing process

How do we form patterned/embossed stainless steel sheets?

For conventional rolling manufacturing processes such as inox steel rolling or rolling of other metal sheets, plain and flat rolls are usually used. In contrast to that, pattern rolling is possible only by using individually designed, custom manufactured structured rolls, which make pattern rolling a rather specialized process.

A wide variety of structures and designs can be etched onto these rolls, which are made of extremely hard special stainless steel. These structures are defined on the one hand by the technical requirements and parameters of the forming, embossing process (structure depth, working width, sheet thickness, material hardness and others) and on the other hand, of course, by the customer's design requirements.

The properties of patterned stainless steel

Traditionally, the pattern rolling found its first applications in industry, namely in mechanical engineering. The rolling manufacturing process gives the stainless steel sheets properties such as:

- Rigidity

- A significant weight saving by using thinner, lighter base material

- Robustness

- Slip improvement or slip resistance

In the course of time, the inox metal sheets produced using different pattern rolls became more and more popular in the field of architecture and design. In those applications, their advantageous properties such as optical flatness and scratch resistance came into play.

Thus, the metal surfaces of different alloys, such as stainless steel, receive technical, functional and visually high-quality added value through the pattern rolling manufacturing process, making them an attractive and beneficial material in many markets.

What is the pattern rolling process?

As already noted above, when design rolling (sheets rolled on one side – embossed sheets) or pattern rolling (sheets rolled on both sides), the rolling stock, i.e. the coils or sheets, is subjected to a rolling process with the aim of applying the structure of the respective roll(s) onto the sheets (on one or both sides).

The manufacturing technology is relatively uncomplicated and cost-effective. The cold forming of a stainless steel or metal sheet or rather of its surface takes place mostly in coil form, but it is also possible in sheet form.

The selection of materials that can be rolled includes:

- Stainless steel

- Steel

- Aluminium

- Brass

- Copper

- And other non-ferrous metals

All these materials can be improved in their surface quality and functional performance by pattern rolling.

Possible dimensions:

mirrorINOX offers custom-sized patterned and embossed stainless steel sheets:

|

Length: |

max. 6,000 mm max. 1,500 mm max. 2.0 mm |

Patterned stainless steel sheets by mirrorINOX – single or double-sided

mirrorINOX offers metal sheets rolled on one side (embossed-rolled or design-rolled) and on both sides (pattern-rolled) and has a high level of specialized knowledge and many years of experience in this stainless steel surface treatment.

While sheets that are design-rolled on one side meet requirements such as a higher-quality appearance and resistance to scratches, the properties of sheets that are pattern-rolled on both sides, such as even greater optical flatness and rigidity and interesting light reflections, are also highly appreciated.

Regardless of the intended use and the desired effect, mirrorINOX is happy to advise you and find the ideal solution for you in this product group.

As for many other special surfaces, mirrorINOX is the leading inox steel sheet and plate manufacturer and your consultant and supplier for the highest quality material even for the most difficult applications in the field of architecture, façades, yacht and shipbuilding, shop construction or product design.

Our range therefore not only includes pattern-rolled and embossed stainless steel sheets, but also the following finishes of stainless steel and other metals:

- Nano-coating

- PVD/TiN-coating

- Bead blasting

- Fluid forming

- Polishing

- Mirror polishing

Patterned Finishes

Stainless steel surface finishing: our wide range of finishes

Our stainless steel surface treatment services at a glance

mirrorINOX offers different types of stainless steel surface finishing processes:

Polishing/Mirror polishing

Polishing or mirror polishing is a mechanical inox surface treatment in which the surface of the primary material is first leveled and any defects are removed. Only then is the actual polishing/mirror polishing carried out, producing the required mirror quality of the stainless steel surface.

mirrorINOX polishing lines and techniques are world-leading in terms of technological improvements, the dimensions of the polishable stainless steel sheets/plates and the surface quality of the mirror finish.

The largest-ever mirror-polished sheet, measuring 14,973 x 3,347 x 16.0 mm and weighing 6,415 kg, was also produced by mirrorINOX at the end of 2018.

mirrorINOX combines a number of different polishing and mirror polishing techniques and media with a great deal of experience to produce Mirror No.7, Super Mirror No.8, Marine Mirror No.9. and Perfect Mirror No.10® qualities on a wide range of stainless steel grades such as:

- AISI 430

- AISI 304

- AISI 316Ti

- AISI 316L

- AISI 318LN ("Duplex" stainless steel)

PVD-coating

This surface technology makes it possible to coat stainless steel sheets or parts with an extremely thin layer of approx. 0.2-0.3 μm by vaporising a metal substance in a high vacuum using suitable gases and other parameters.

This so-called arc process, unlike other coatings such as galvanic processes, does not release any toxic or harmful substances. In addition, it is possible to apply a controlled coating in a choice of colours regardless of the base material used (black, gold, rose gold, and more).

PVD/TiN-coatings have a natural metallic appearance and thus stand out from the majority of other types of coating.

nanoINOX®-coating

This innovative nanoINOX® method of surface treatment, based on the sol-gel process, enables unlimited design diversity and gives the material groundbreaking, functional properties such as:

- AntiFingerPrint (AFP),

- Easy-To-Clean (ETC),

- Antibacterial effect,

- Change in electrical conductivity

- Etc.

In our self-configured, state-of-the-art coating line, the inox sheets are pre-treated and cleaned according to the strictest criteria. Afterward, the individually formulated coating medium is applied via a rotary atomizer and then hardened in a 250°C continuous flow heater. This ensures high resistance and durability of the coating.

In addition to fascinating visual appearances, all our nanoINOX® coatings also offer excellent protection of the substrate against environmental influences such as corrosion, weathering, dirt, vandalism and graffiti thanks to the so-called "Lotus" or Easy-To-Clean effect, i.e. the surfaces do not get dirty as easily and are easier to clean.

It is also possible to apply a transparent protective coating to a wide variety of base surfaces, see more on this page.

Compared to alternative materials, nanoINOX® surfaces significantly improve hygiene conditions and save customers cleaning costs, detergents and water, thus reducing costs and protecting not only your budget but also our environment.

Beadblasting

In many areas of industry, for example, plant or mechanical engineering, different blasting processes are usually used to remove various irregularities (chips, scale, etc.) from stainless steel surfaces for later processing or to make the surface of the stainless steel more uniform and matt.

mirrorINOX goes further with its process (injector/venturi blasting) and, by blasting with different glass, ceramic or corundum media, creates decorative and functional surfaces on the metal of the highest quality which are uniformly matt, directionless, low-reflection or reflection-free and of very high homogeneous roughness.

These bead-blasted surfaces are created on stainless steel and aluminium, and also on non-ferrous metals such as brass or copper by bombarding them with a wide variety of blasting particles ranging from fine to coarse and using a wide range of parameters such as pressure, blasting angle and speed.

Here, custom stainless steel/inox and other metal sheets with maximum dimensions of 2,000 mm (width), 6,000 mm (length) and 30 mm (thickness) can be surface treated.

Grit Polishing

Grit-polishing and brush-polishing variants can be used to even out the rather unattractive factory surfaces and to remove minimal defects and imperfections such as light scratches that can be found on them. It is also possible to achieve specified roughness values (Ra) by grit polishing the sheets for technical applications, such as tank or silo construction (e.g., for mixing, brewing, fermentation, and other processes).

mirrorINOX creates a range of aesthetically attractive surfaces with a variety of grit-polishing and brush-polishing techniques.

Among other things, the use of abrasive belts with different grit sizes creates surfaces with a SATIN or HAIRLINE finish, both longitudinal and perpendicular.

The polished finish of the stainless steel sheets or plates can be changed and adapted by using different grit sizes (K80, K100, K240, etc.) and settings on the machine.

Vibration Polishing

A special type of inox grit polishing is vibration polishing, also known as angel hair, rotation polishing or non-directional polishing.

With this optically very demanding surface finishing, a directionless, homogeneous and more or less matt surface is achieved on the stainless steel.

We record the production of each individual sheet very precisely by measuring the roughness depth and the degree of gloss, as well as by expertly assessing the optical appearance of the polished sheets.

The process used by mirrorINOX offers a wide range of designs and types of polishing design patterns combined with high capacities for even the most extensive projects.

Fluid Forming

The technology of fluid forming is only possible through the use of an enormously powerful press (120,000 t!!!), which was originally developed for forming processes in the automotive industry. It is used to form mirror-polished, grit-polished, bead-blasted or PVD/TiN and nanoINOX® coated metal surfaces.

In this way, stainless steel sheets and alternative materials such as steel, aluminium or non-ferrous metals are pressed under high pressure with a liquid onto a specially created tool and a variety of three-dimensional shapes and surface structures are produced.

You can find an initial selection of structures on this page.

mirrorINOX also offers many other customized possibilities for which physics is a limit in a few cases, but almost never the customer’s creativity.

Pattern Rolling

With this stainless steel surface finishing technique, the metal sheet is design- or pattern-rolled in a one- or even two-sided pattern rolling process.

These rolling processes improve the technical properties of the stainless steel such as robustness, rigidity and scratch resistance, as well as visual attributes such as optical flatness or reflection behaviour.

In this area, mirrorINOX offers the traditional designs such as LEINEN, 5WL, 6WL or 7WL, but also, depending on the project size, new solutions created according to customer requirements.

mirrorINOX: Your expert for stainless steel surface finishing unites know-how and innovation

mirrorINOX is a young start-up company and was only founded in 2016.

In this short time, mirrorINOX has succeeded in creating unique solutions for the surface finishing of stainless steel/inox, aluminum and non-ferrous metals with considerable know-how and great motivation. We are always highly creative and extremely flexible to the wishes and demands of our clientele.

Materials from our production can already be found in numerous architectural applications, art projects and many other examples worldwide.

Whether you are interested in conventional or completely new processes in the surface treatment of sheet metal, whether your requirement is for one custom stainless steel sheet/plate or 12,000 m², whether you want to improve the surfaces of small parts or refine those of large projects: we at mirrorINOX are your ideal contact for all these questions!

Because stainless steel surface treatment is our core competence and close to our hearts.

Our tools and machines for stainless steel surface treatment

In our production plant at the newly built site in Cleebronn, Germany, the most modern machinery, processing lines, devices, tools and production equipment are used to apply the various types of mechanical and coating surface treatments on stainless steel, aluminum and other non-ferrous metals according to the latest state of the art:

Mirror polishing lines

- World's largest mirror polishing plant for sheet metal in dimensions of 16,000 x 4,000 mm

- mirrorINOX polishes mirror qualities for the highest demands: Super Mirror No. 8, Marine Mirror No. 9 and Perfect Mirror No. 10®

- Polishing of thicknesses over 20 mm and special stainless steel grades such as AISI 318LN (Duplex) or Quarto

PVD/TiN systems

- Line with an extremely large chamber for inox sheets/plates up to 6,000 mm long and 2,000 mm wide

- Line with compact dimensions for construction and small parts made of stainless steel, such as fittings, pipes, valves and many others

nanoINOX®-coating plant

- Specially configured continuous plant using the sol-gel process

- Heat hardening at 250°C

- Unlimited possibilities in terms of colours, designs and functions due to customized formulations and application processes

Longitudinal and perpendicular grit polishing line

- Ra grit polishing for stainless steel and metal sheets up to 20 mm

- Longitudinal and perpendicular design grit polishing

- Vibration polishing, non-directional polishing

- Cross grit polishing

Beadblasting line

- Blasting with glass and ceramic beads

- Various blasting patterns from smooth to rough in architectural quality with high accuracy and uniformity

Measuring technology

mirrorINOX has the most modern measuring equipment and techniques at its disposal to check the high-quality surfaces for colour, reflection, roughness and gloss values, as well as for criteria such as durability, workability and others, and to record this data.

Peripheral machinery and equipment

To support and complete the production facilities listed above, mirrorINOX has a variety of supplementary machinery and equipment, handling, transport and foiling systems, as well as ultra-modern cleaning lines which, through intensive cleaning, ensure surfaces with the level of cleanliness we require for further processing or coating.

The benefits of stainless steel surface finishing: improved design and properties

Thanks to its passive layer, stainless steel (also called inox) is a corrosion-resistant alloy steel that is used in a great many areas of industry and architecture due to its remarkable properties: building construction, art sculptures, elevators, but also food and medical industry, appliances, boat accessories, etc.

In order to further improve products and applications made of stainless steel, both in terms of their visual appearance and their functional properties, additional surface treatment is increasingly being applied. Brushed stainless steel is traditionally a very common and well-known example of this.

Visual stainless steel surface finishing and improvements are of great importance, especially in architecture.

Colour, gloss, reflection and other design elements are playing an increasingly meaningful role in facades, roofs, wall and ceiling cladding, lifts, escalators, doors, counters and many other applications.

In product design and mechanical engineering too, the visual appearance of stainless steel surfaces is of ever-increasing importance, making the product both attractive and high quality.

There is also a growing number of surface treatments that support and improve the functions of stainless steel or give stainless steels completely new properties.

For example, surface treatment can increase:

- chemical resistance

- weathering resistance

- corrosion resistance

- electrical conductivity.

The application of antibacterial and easy-to-clean coatings, which reduce maintenance and improve the hygienic condition of the stainless steel surface, also creates an even wider field of applications for stainless steel.

All about the surface of stainless steel

Although stainless steel as a material has many positive characteristics, such as easy availability, high resistance and good workability, it is only available in an extremely limited selection of surface variants from inox plants.

The "2B" (matt) and "BA" (shiny) finishes are the most common stainless steel finishes for the lower thicknesses (e.g., 1mm, 2mm, 3mm). However, depending on the factory, material, thickness and batch, they are not of very high optical quality and the applications are visually very limited or can only be used technically.

In particular, the factory surfaces of hot-rolled or Quarto sheets are not suitable for fabrication or use in the architectural or design sector.

mirrorINOX offers a variety of proven and newly developed surface treatment technologies to enhance the attractiveness and functionality of stainless steel. Thanks to our expertise, we are able to provide solutions even for the "extreme" surfaces of hot-rolled or Quarto sheets or plates.

Be it longitudinal or perpendicular, grit polishing, alternative grit-polishing methods, bead blasting, mirror polishing, PVD/TiN colour coating, nanoINOX® anti-fingerprint coating and other processes, mirrorINOX is the leading expert in stainless steel surface finishing!